REALITY: Future of Footwear

overview

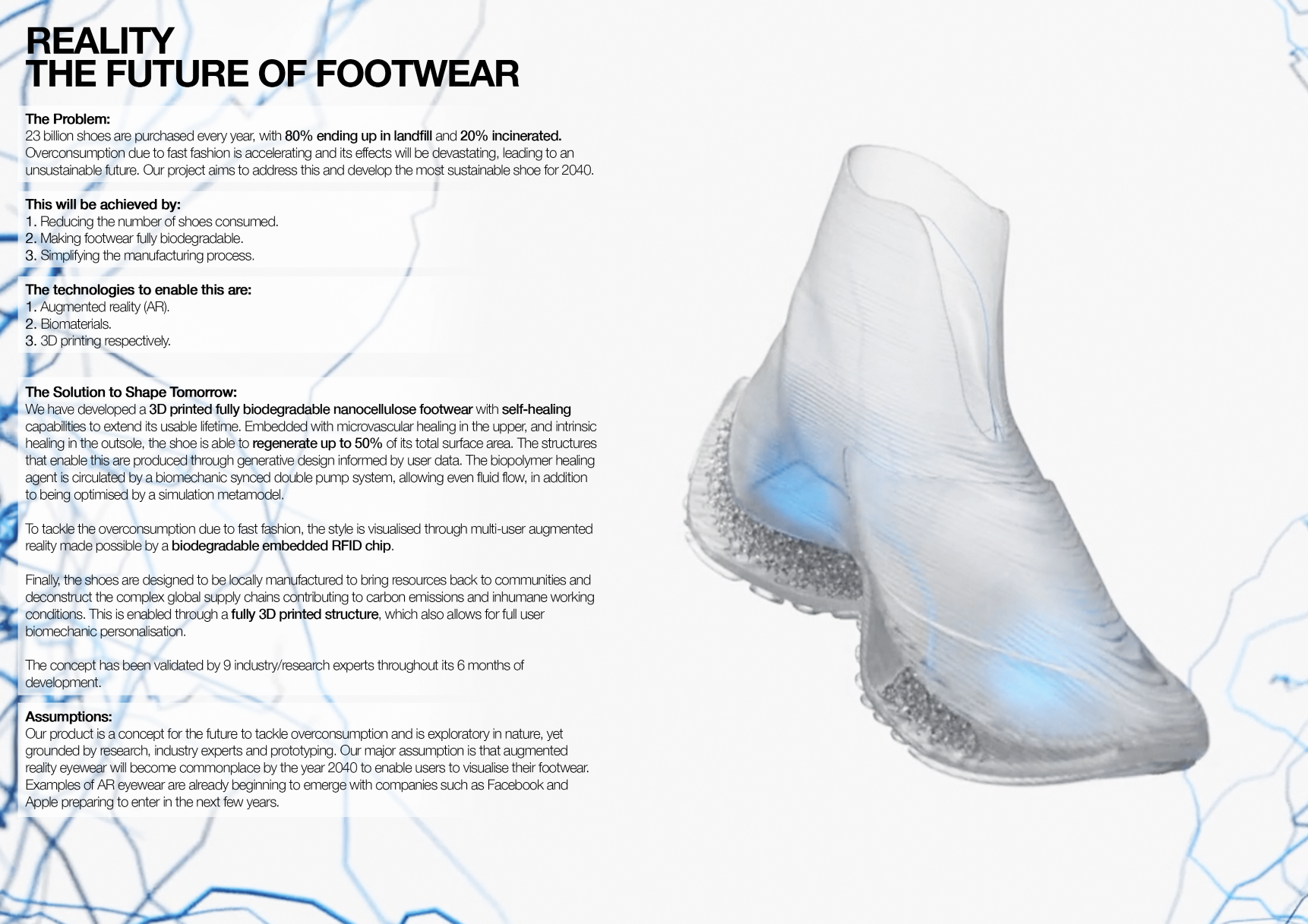

REALITY: THE FUTURE OF FOOTWEAR – making shoes sustainable through AR digital shoe overlays to tackle the overconsumption caused by fast fashion, and 3D printed biodegradable self-healing technology to extend usable life and allow them to return to nature.

the challenge

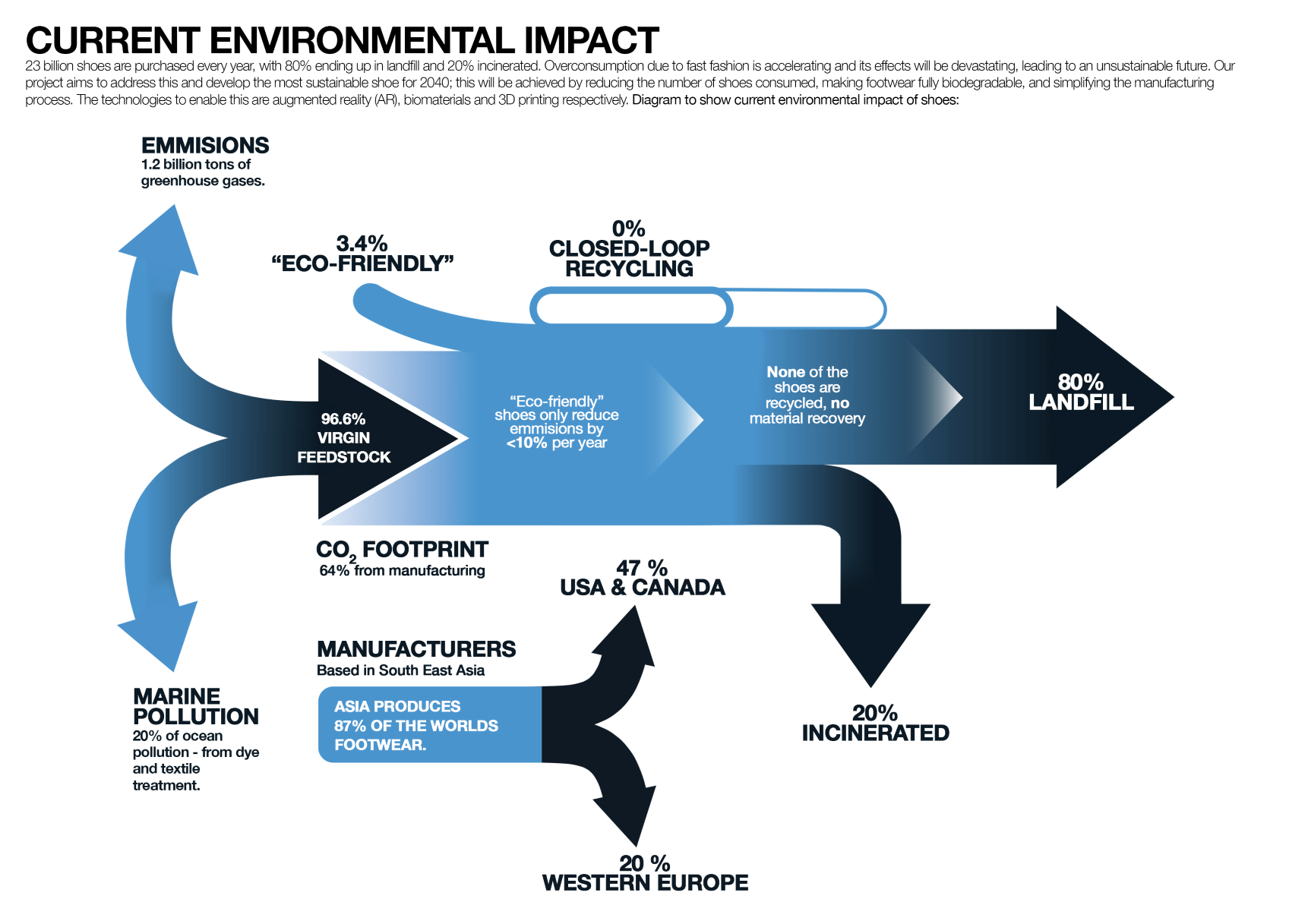

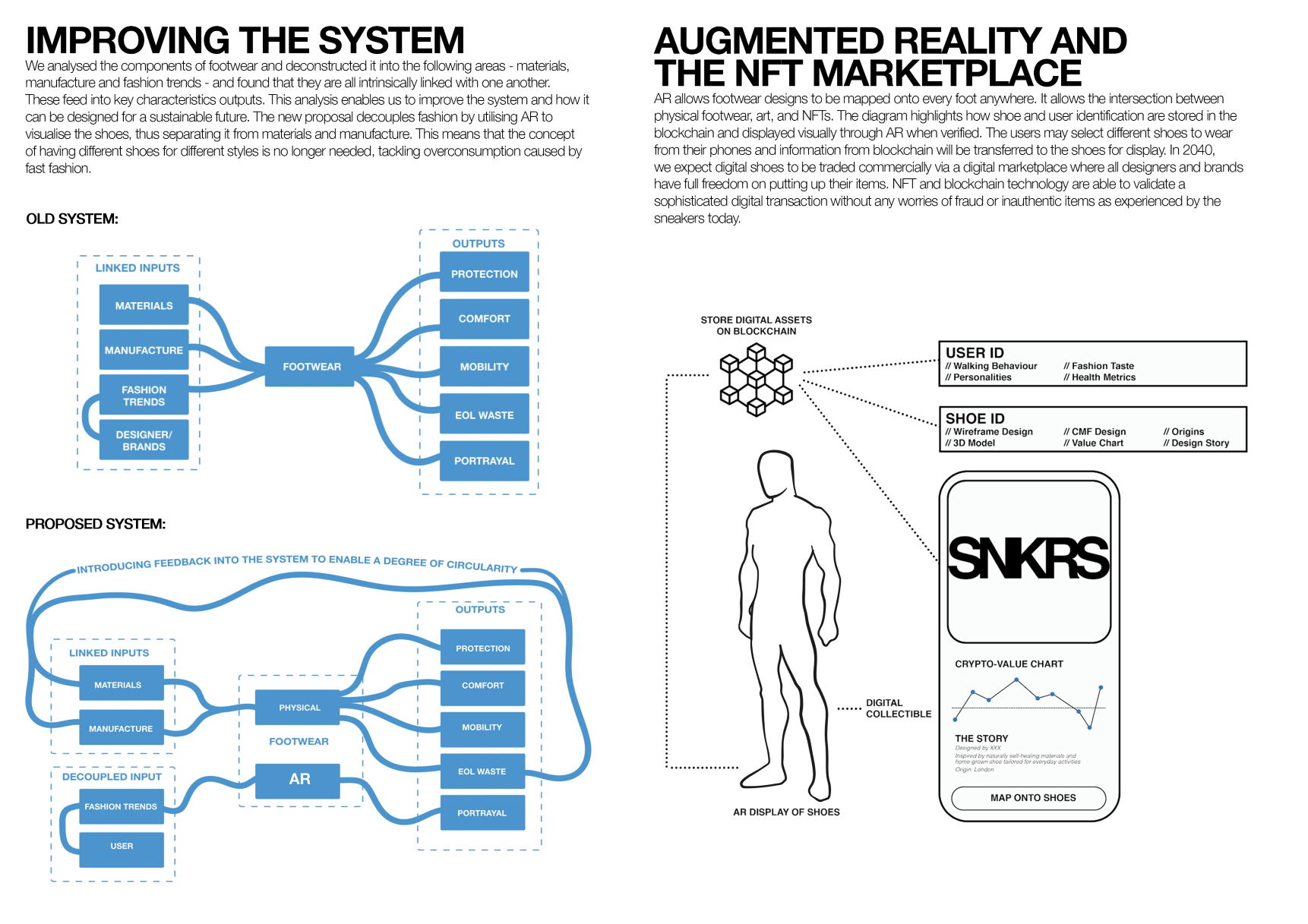

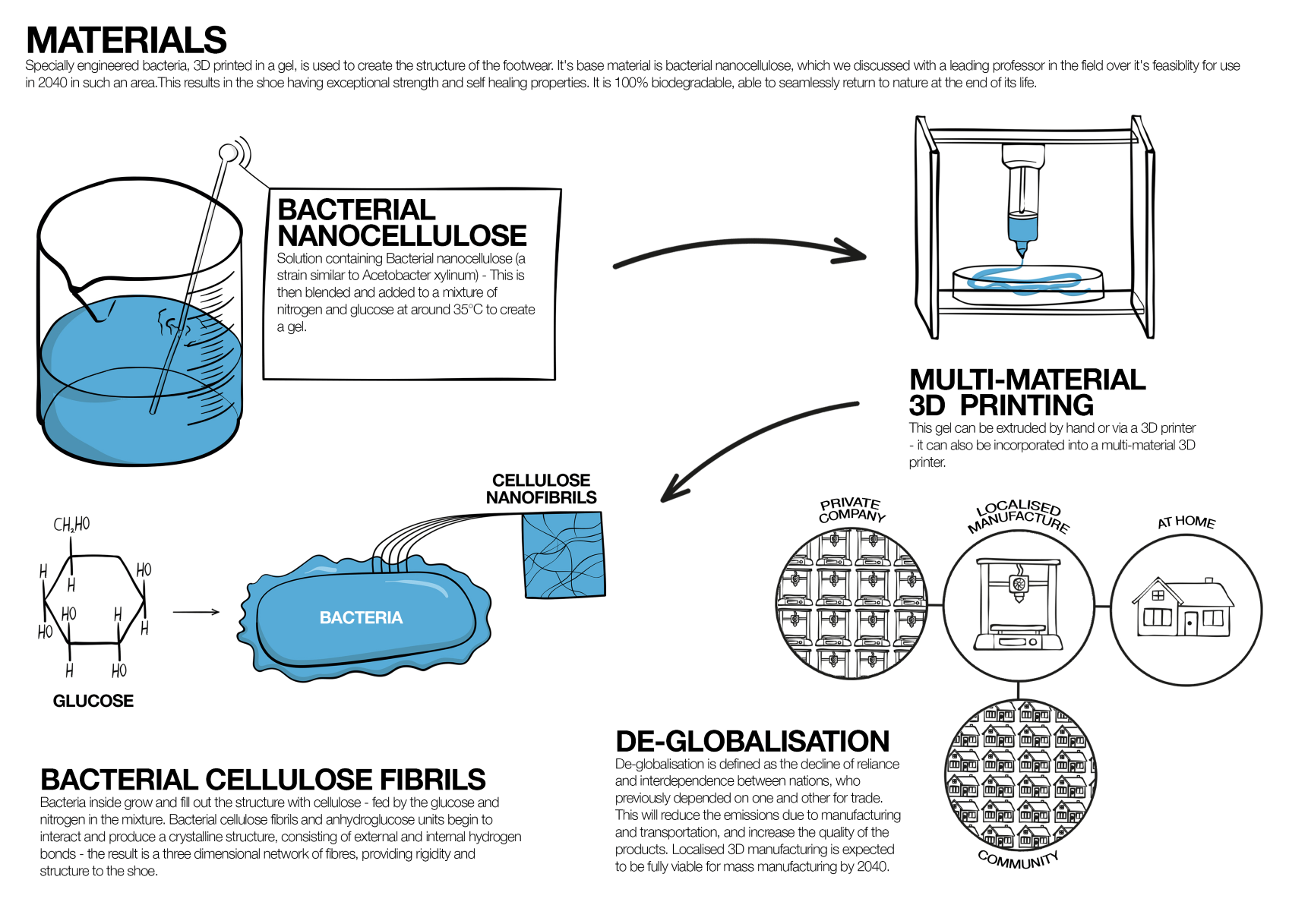

23 billion shoes are purchased every year, with 80% ending up in landfill and 20% incinerated. Overconsumption due to fast fashion is accelerating and its effects will be devastating, leading to an unsustainable future. Our project aims to address this and develop the most sustainable shoe for 2040; this will be achieved by reducing the number of shoes consumed, making footwear fully biodegradable, and simplifying the manufacturing process. The technologies to enable this are augmented reality (AR), biomaterials and 3D printing respectively.

the result

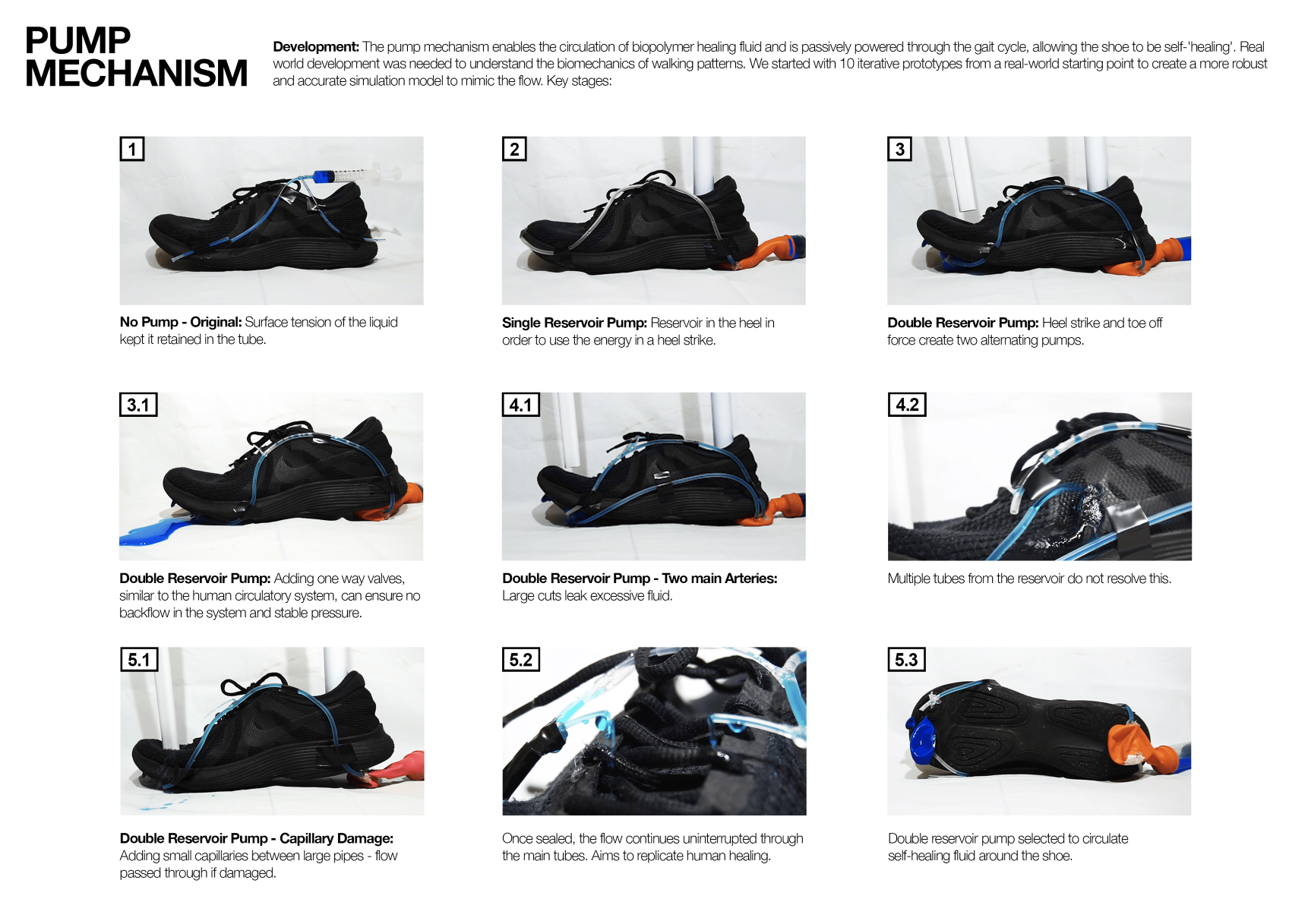

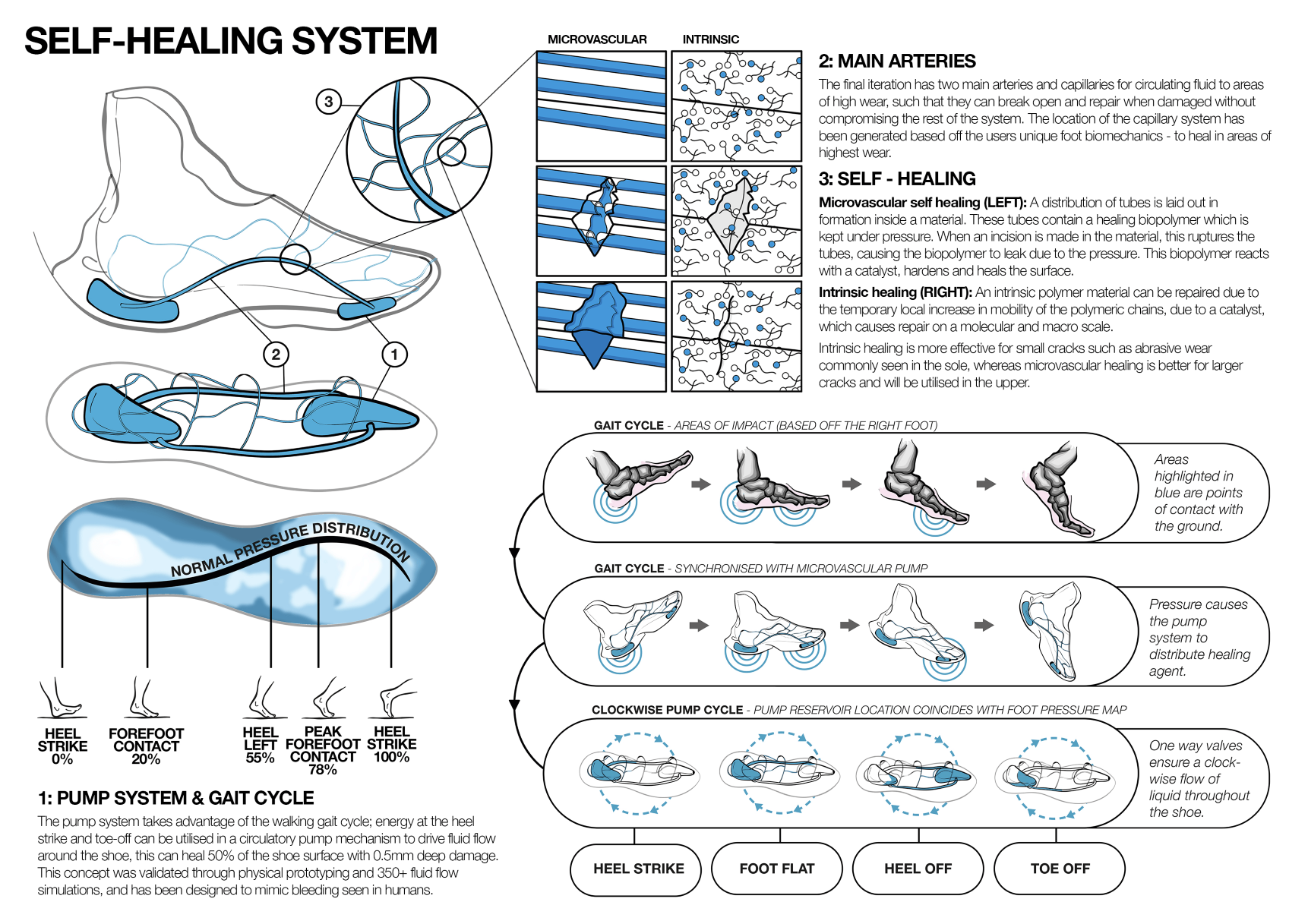

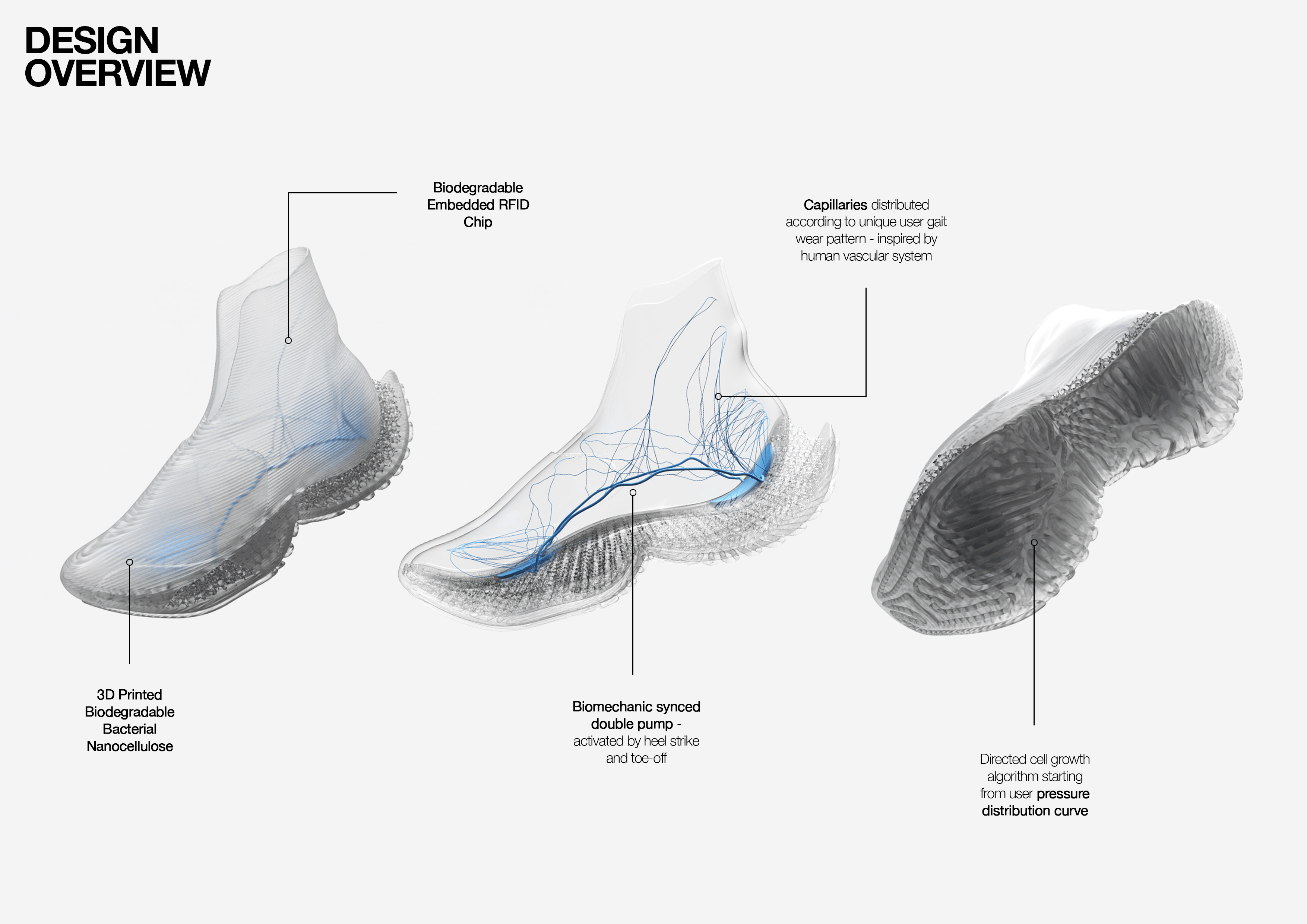

We have developed the concept of a 3D printed fully biodegradable nanocellulose footwear with self-healing capabilities to extend its usable lifetime. The shoe is able to regenerate up to 50% of its total surface area, through a user specific microvascular healing structure. The biopolymer healing fluid is circulated by a biomechanic synced pump system. This was physically prototyped and digitally iterated over 350 simulations. The shoe was created in Solidworks and Grasshopper. The pump mechanism is a major innovation that has scope beyond the sustainability industry. Finally, the shoes are designed to be locally manufactured to bring resources back to communities and deconstruct the complex global supply chains contributing to carbon emissions and inadequate working conditions. This is enabled through a fully 3D printed structure, also allowing for full user biomechanic personalisation.

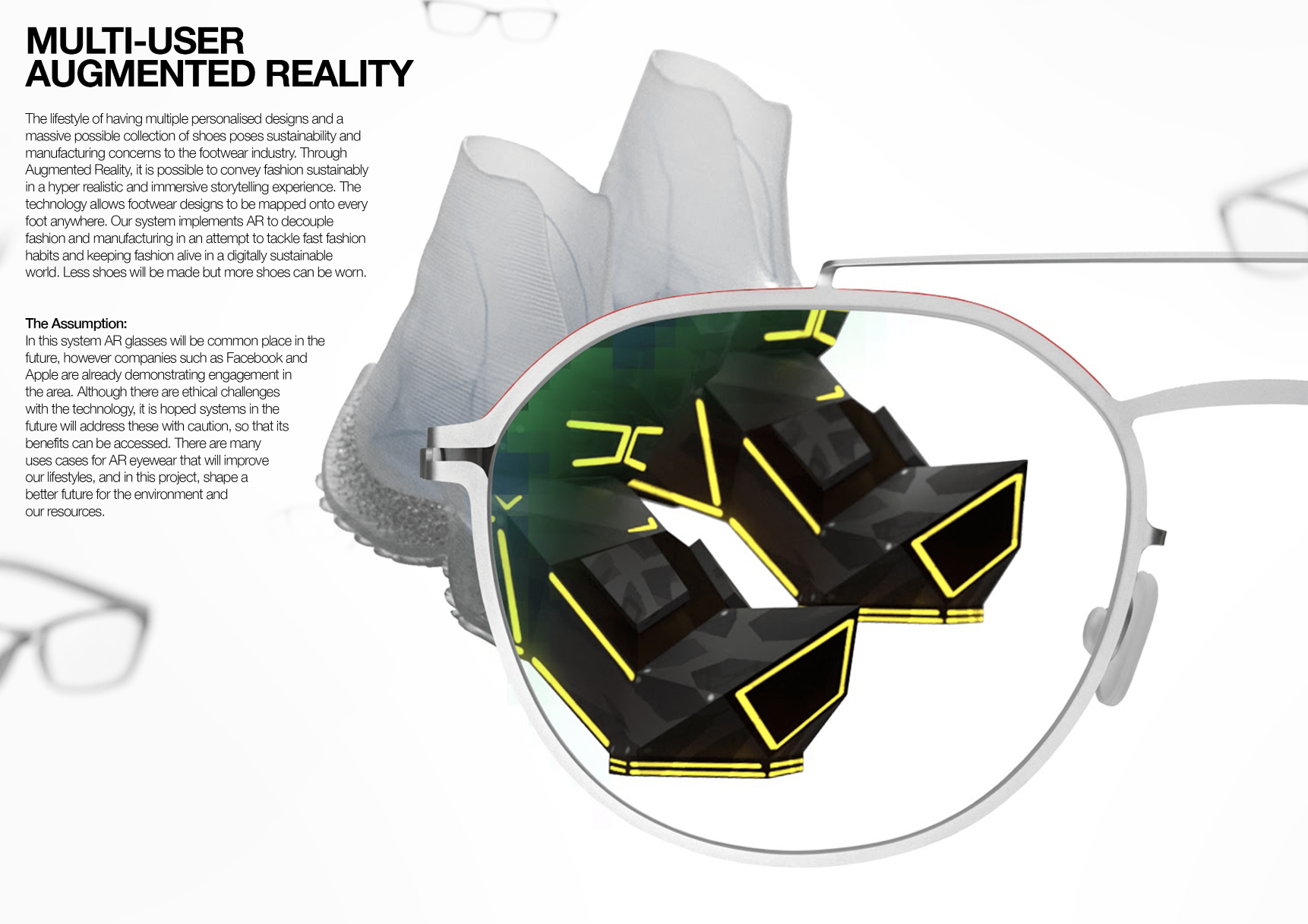

Our concept enables a digital market based on NFTs, where footwear can be purchased online, then worn in real life, retaining the perceived value of fashion without mass consumption of physical materials or waste.

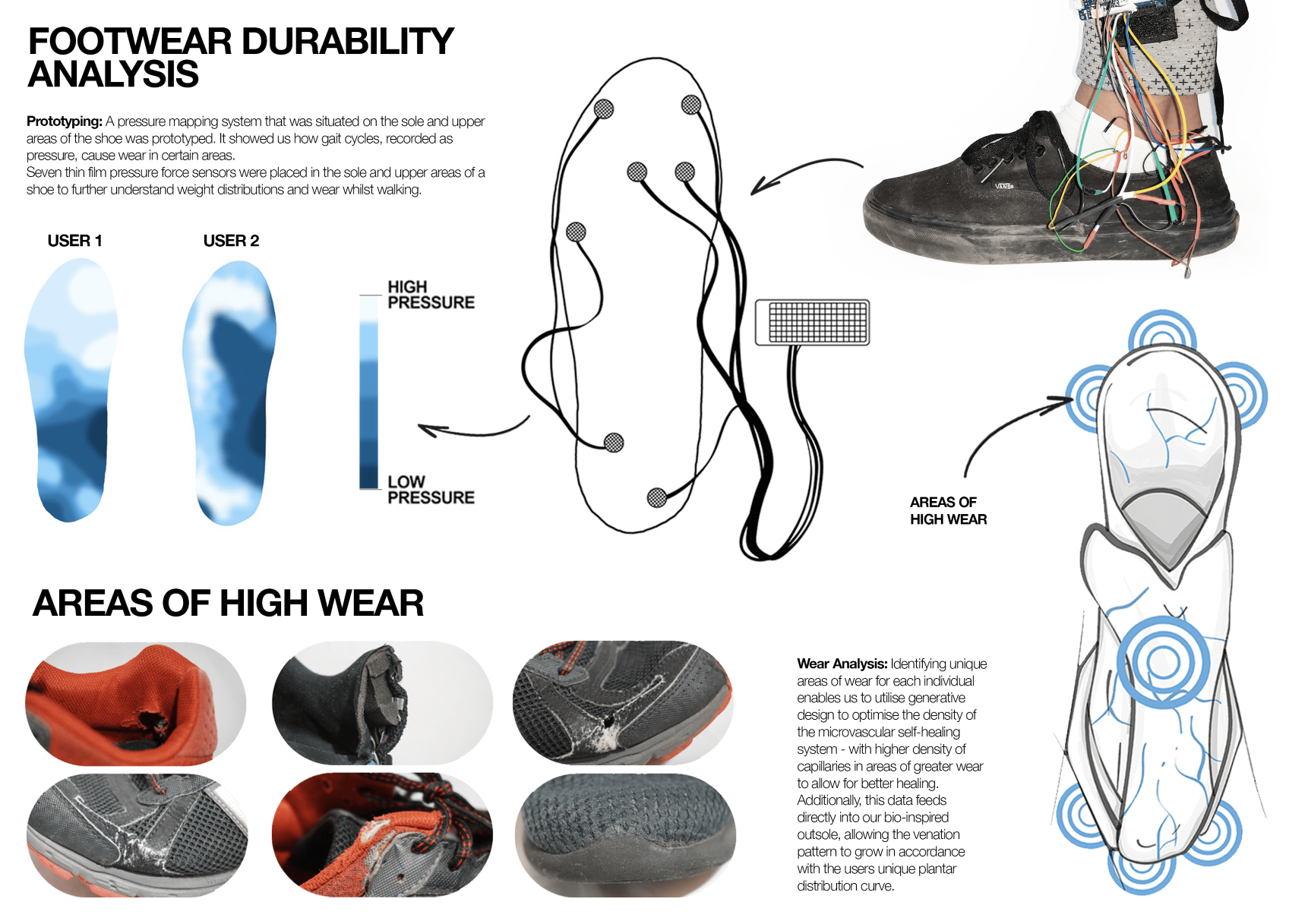

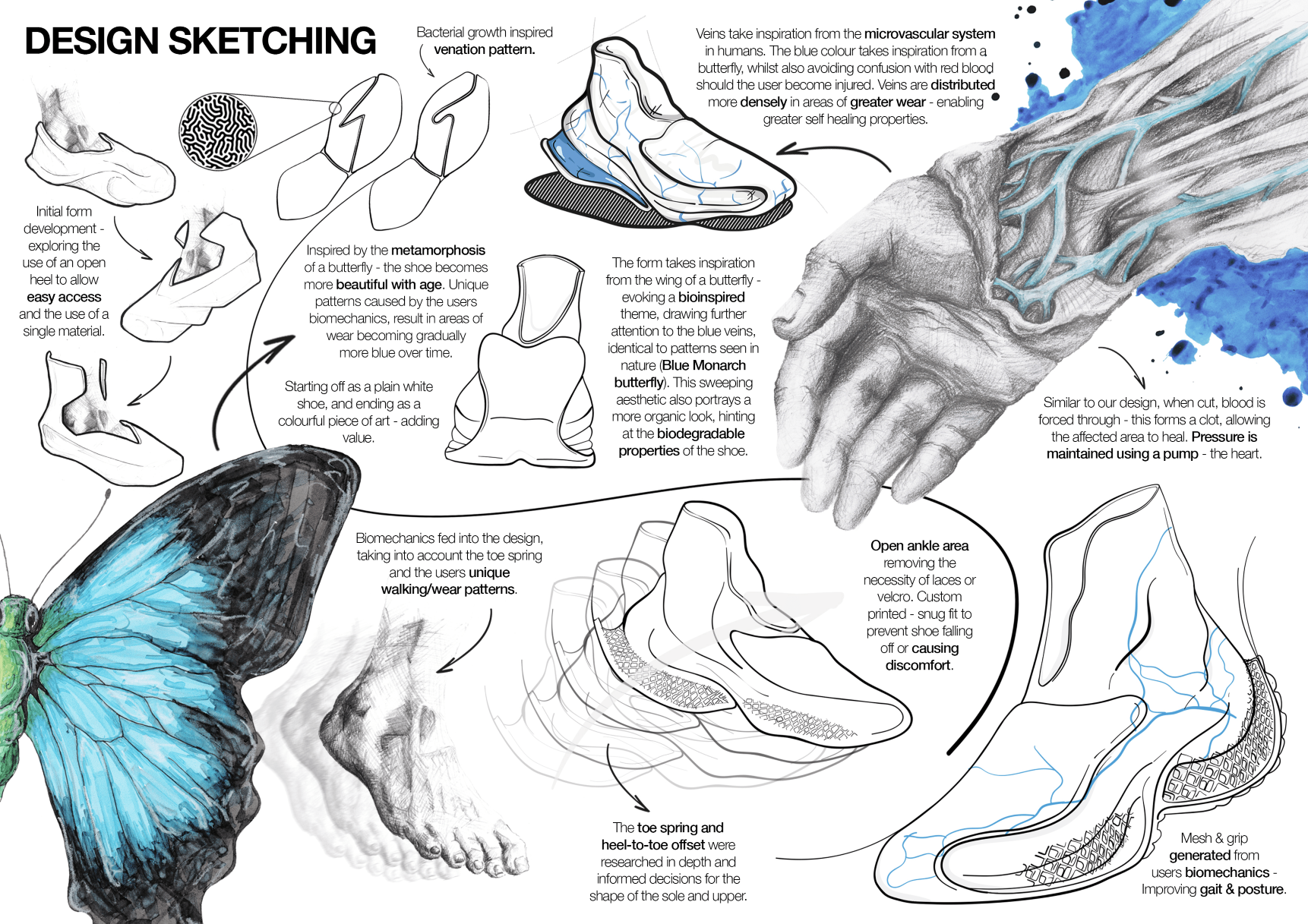

A RFID chip printed on cellulose nanofibrils, is integrated in the shoe, enabling Multi-user AR. It was found that 3 key areas, the toe box, outer heel, and mid upper, have the highest abrasion based on visual inspection of different user footwear. We analysed shoe pressure points and gait-based wear to create a generative design model that makes a user-unique healing network for transporting biopolymer healing agent. This is circulated by a pump system that utilises the heel strike and toe-off to compress internal chambers. Fluid is directed through one way valves enabled by 3D printing. The dynamic pressure was tuned to replicate the human vascular system for ‘bleeding’. The CFD model was informed by initial prototyping. We also created a unique outsole pattern, mimicking morphogenetic growth, aiming to improve user gait and posture.

Development was validated by over 9 industry experts and was pursued over 6 months. My contribution to the project was the 3D modelling in Solidworks, computational design in Grasshopper, CFD simulations, calculations, project strategy, networking, product renders, animations and research.

The project has been featured in the Global Grad Show, New York Tech Fashion Week 21, Crypto Fashion Week 21, Design Week Article and won the Young Pioneer category in the E&T Innovation Awards 2021 by the Institute of Engineering and Technology.

TEAM

Shafae Ali, Alfie Mcmeeking, Premal Gadhia, Andy Ferdinand, Judith Weill

year

2021